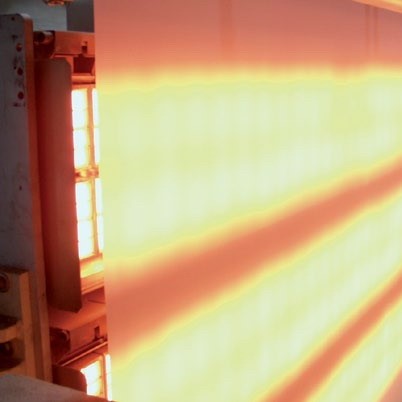

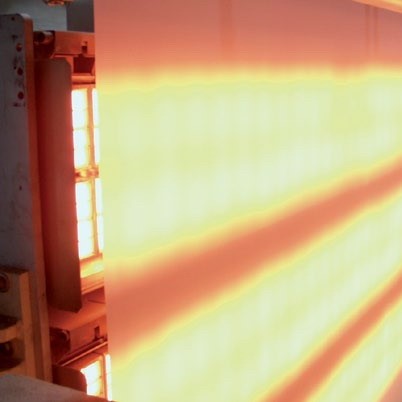

Infrared glass fiber cloth pre drying heating system

Principle:

Infrared ray is a kind of invisible light, which propagates in a straight line at the speed of light, and has certain penetrating power. After being absorbed by the object, infrared ray can be converted into heat energy rapidly, so it has a strong heating effect. After water absorbs infrared, the temperature rises rapidly and evaporates. This is the principle of infrared drying. The heating speed of infrared ray is several times faster than that of conventional hot air heating. Therefore, infrared ray can be used in the situation that needs rapid heating and drying. Metal fiber burner is especially suitable for the pre drying of textiles. In addition, using them has the characteristics of hot and cold. This ensures absolute safety in all operating modes. In addition to the fast cooling characteristics of the gas infrared heater, the air supply and exhaust system ensures immediate cooling when the machine is stopped or the textile mesh is stopped. A single heater can be controlled individually, so the adjustment is more flexible, so that the single heater row can adapt to different fabric widths. To achieve the effect of high efficiency, energy saving and environmental protection.

Product advantages:

1. With infrared radiation heating as the main heating, convection heating as the auxiliary (65% radiation, 35% convection), Billy electric drying energy saving 30-50%;

2. The structure is made of high temperature resistant alloy fiber, which is durable.

3. The mechanical fire-proof device is designed. At the same time, the electronic monitoring tempering detection needle and the control part of the whole system are linked to make the whole system safe, reliable and energy-saving burner system in Colleges and universities.

4. It can be combined into different specifications of heating equipment according to the needs, and the combustion surface can be installed in any aspect of the upper, lower and lateral sides.

Easy to replace.

5. Low Co: due to the complete premixed combustion, the combustion is more sufficient, and the CO < 25pp is more environmentally friendly in the infrared combustion mode. Low NOx: < 10ppm in infrared combustion mode

6. Natural premixing: the preset gas / air premixing device enables the burner to obtain the best gas / air ratio. And the whole process is completed automatically without manual intervention.

Size:

1. The calorific value per unit area is 150 ~ 250KW / m2

2. The surface temperature can reach 800 ℃

3. The high regulation ratio can reach 1:10

4. Heat range: 0 / 5 ~ 5wkcal / h

5. The dimensions are designed according to the customer's requirements

6. Fuel used: LPG / NG

Industry application:

1. Food drying

2. Coating drying and heating

3. Textile printing and dyeing drying, coating drying and heating

4. Paper drying and heating

5. Grain drying and heating

6. Washing, drying and heating

7. Drying of latex products

8. Gas water heater

9. Road asphalt pavement repair, etc