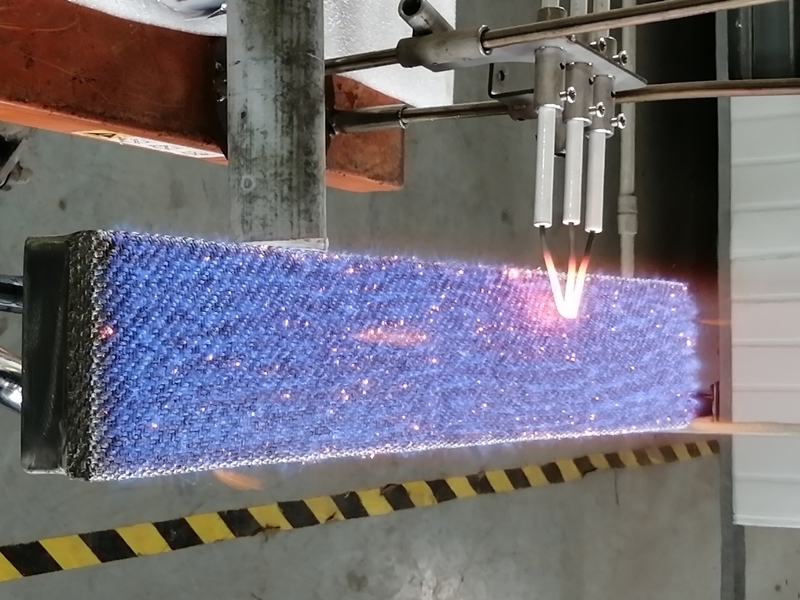

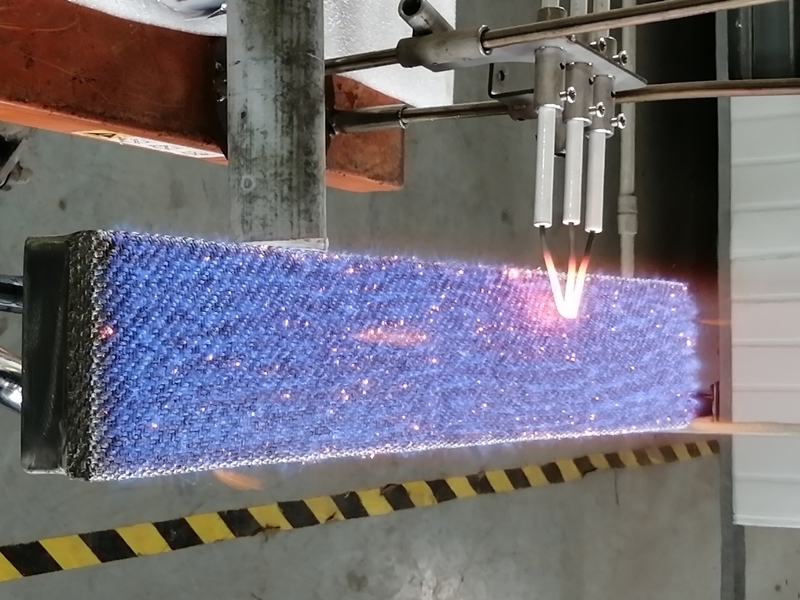

Flat plate low nitrogen metal surface burner

principle:

Infrared ray is a kind of invisible light, which propagates in a straight line at the speed of light, and has certain penetrating power. After being absorbed by the object, infrared ray can be converted into heat energy rapidly, so it has a strong heating effect. Different materials have different absorptivity to infrared rays. Water is one of the substances that can strongly absorb infrared rays. After water absorbs infrared, the temperature rises rapidly and evaporates. This is the principle of infrared drying. Infrared heating is several times faster than conventional hot air heating, so it can be used in situations requiring rapid heating and drying;. It is a heating equipment that uses far-infrared radiation as heat source for drying. It has the characteristics of uniform heating, continuous operation, energy saving and environmental protection and effectively reducing the bitterness and astringency. According to different industrial applications, the range of infrared division is also different. In practical industrial applications, infrared rays above 2.5 & mu; m are called far infrared. In the far-infrared band, the material dry matter has about 20% ~ 80% absorptivity, while the water has a larger absorption rate in the band of 3 ~ 6.5 & mu; m and 15 & mu; m, that is to say, in the far-infrared band, the material dry matter and moisture have strong radiation absorption capacity.

Industry application:

1. Food drying

2. Coating drying heating

3. Textile printing and dyeing drying, coating drying and heating

4. Paper drying heating

5. Grain drying heating

6. Washing, drying and heating

7. Drying of latex products 8. Gas water heater

9. Asphalt pavement repair, etc

product advantages:

&In this paper, a new method is proposed=“ http://www.shadj.com.cn "> infrared radiation heating < / a > is the main heating method, and convection heating is the auxiliary (65% radiation, 35% convection), and Billy electric drying can save 30-50%;

2. The structure design is made of high temperature resistant alloy fiber, and it is made of high temperature resistant alloy fiber, which is durable.

3. The mechanical fire-proof device is designed. At the same time, the electronic monitoring tempering detection needle and the control part of the whole system are linked to make the whole system safe, reliable and energy-saving burner system in Colleges and universities.

4. It can be combined into different specifications of heating equipment according to the needs, and the combustion surface can be installed in any aspect of the upper, lower and lateral sides.

Easy to replace.

5. Low Co: due to the fully premixed combustion, the co & lt; 25pp is more environmentally friendly in the infrared combustion mode. Low NOx: in infrared combustion mode, & lt; 10ppm, equivalent to the European standard.

6. Lower noise: the structural design of casting integrated molding can effectively avoid airflow noise. The combustion noise can be controlled below 60 dB, which can realize quiet combustion, which is lower than the national class 1 noise standard. It meets the national class II environmental noise standard, making the working environment more comfortable and quiet 7. Natural premixing: the preset gas / air premixing device enables the burner to obtain the best gas / air ratio. And the whole process is completed automatically without manual intervention.

Size:

1. The calorific value per unit area is 150 ~ 250KW / m2

2. The surface temperature can reach 800 ℃

3. High profile saving ratio, up to 1:10

4. Heat range: 0 / 5 ~ 5wkcal / h

5. The dimensions are designed according to the customer's requirements