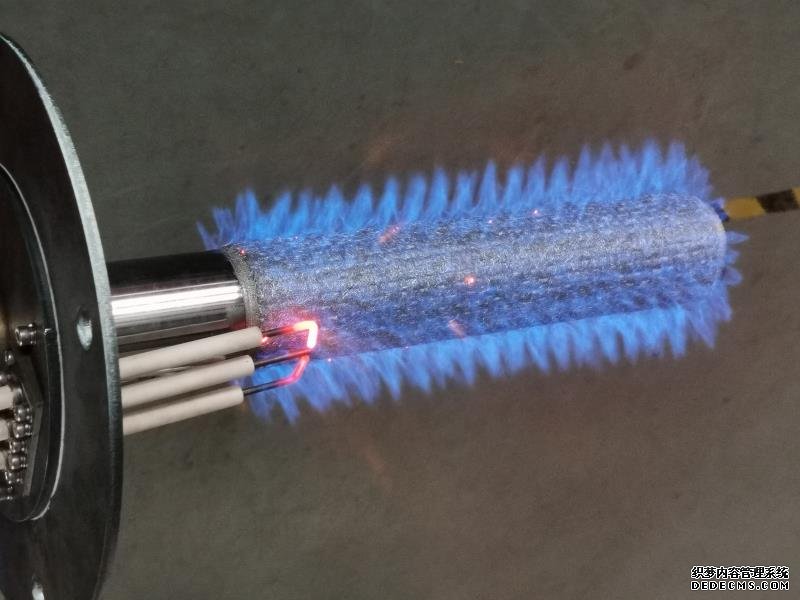

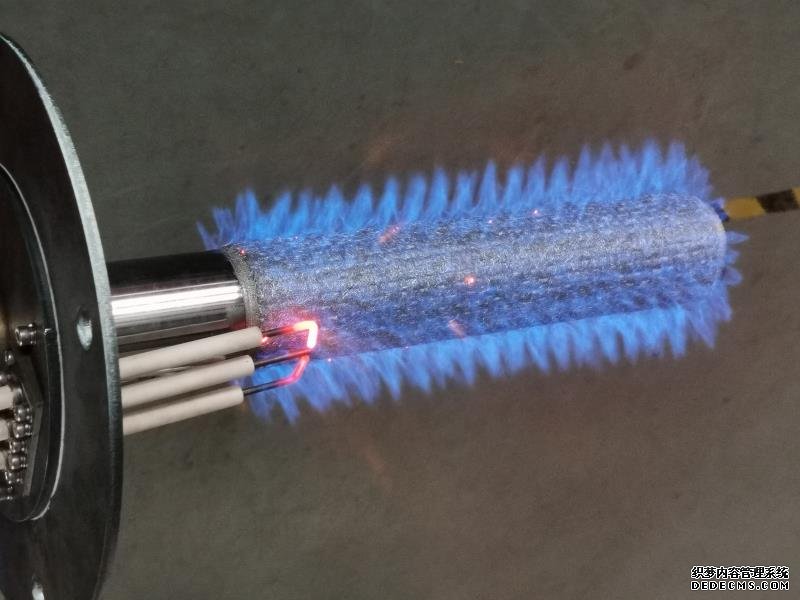

Cylindrical premixed combustion

Adj-zr series burner adopts premixed combustion technology, which is the best solution to solve the low pollution emission, and can achieve high regulation ratio.

characteristic:

1. High adjusting ratio of fuel consumption to meet different temperature requirements of customers without changing furnace head size

2. The structure is very compact, which can obtain high heat output when the combustion furnace head is very small

3. Because the combustion smoke is very clean, the smoke exhaust and ventilation noise are reduced

4. The gas valve group can be directly installed in the combustion control box, with a very compact structure,

5. Using metal fiber alloy as surface material, it has high thermal strength and thermal stress

6. The emission of NOx is very low, which is to solve the problem of ultra-low emission and realize environmental friendliness

7. Liquefied petroleum gas and natural gas can be used

Size:

1. Heat range: 2kcal ~ 120wkcal

2. It is made of Fe Cr al high temperature resistant metal fiber sintered material

3. The calorific value per unit area is 2000 ~ 2500kw / m2

4. The surface temperature can reach 1100 ℃

5. Non standardized customization according to customer requirements

6. The adjustment ratio is 1:5

Application Industry: boiler burner, air heater, furnace heating, food drying, catering equipment, grain dryer, painting and painting room, etc